LCAS has many years of extensive experience in all aspects of aircraft modification, air systems development

Our knowledge and proficiency has transformed the way many industries utilize aircraft for civilian special mission, expand existing system capability, and develop airborne concepts. Most notably, we continue to be the market trail blazer and international leader for Airborne Geophysical Survey Modifications.

Planning

Planning

We began each project engagement with an extensive planning assessment where we look closely at concept feasibility, cost efficiencies, and optimal certification paths. This ensures that the project is launched with strong economic footing and dependable timeline expectations.

Design

Design

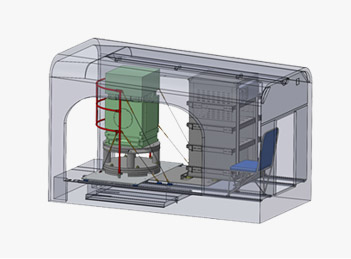

Once the project scope has been clearly defined, we begin the prototype design process modeled in a 3D CAD platform with powerful simulation and design validation capabilities. Concurrently we run our procurement discovery process, to establish component and material selection based on suitability, price and availability.

Engineering Analysis

Engineering Analysis

When the concept is approved by the client, we initiate an engineering design review process. Designs are substantiated using a balanced approach of traditional and higher order analyses. Data generated is documented by LCAS engineers to support certification, testing, manufacturing and maintenance.

Build

Build

As an approved Canadian Aeronautical components manufacturer with an extensive palette of in-house capability, we don’t need to rely on third party availability to turn your concepts into reality. Unlike many other engineering shops, we keep everything under one roof, ensuring time line and cost expectations are kept in check.

Integrate

Integrate

Once the assembly is complete, we will establish an integration plan that is determined by client geo-location and project scope. Based on client requirements, we can send a team to the client’s location to complete the integration, or can provide many of our modifications in “kit form” to be installed by the client. In most cases, the integration is completed at our easily accessible facilities which encompass over 31,000 sq. ft. of indoor ground floor & hanger workspace, centrally located near the GTA (Greater Toronto Area) at Muskoka Airport (CYQA).We are an AMO (Approved Maintenance Organization) with a world class maintenance engineer and integration team.

Ground & Flight Testing

Ground & Flight Testing

LCAS has extensive experience supporting testing for projects of any size. We provide flight test coordination, static load testing, statistical reliability testing as well as conformity inspections and specialized inspections. Our full suite of instrumentation is maintained by LCAS quality assurance and is NIST traceable. LCAS provides flight test coordination through our network of trusted flight test professionals. Our location at the Muskoka Airport is considered a superb base of operations with minimal traffic and ample airspace suitable for testing. coordination through our network of trusted flight test professionals.

Certify

Certify

On projects that require certification, our engineering team have experience coordinating with a number of civil authorities including Transport Canada Civil Aviation, the FAA, EASA, IAC, ANAC and DGCA. Our engineering team can help achieve your Type Design approval via a full Supplemental Type Certificate, Repair Design Approval, or a Serialized Supplemental Type Certificate to best meet your needs and budget. We can provide developmental, validation and testing services for customers seeking a type certificate for their new aircraft design. We offer an efficient, fluid process to help meet your project goals.

At LCAS, we endeavour to bring a “real world” approach when evaluating our client’s needs and are able to offer our experience in generating creative solutions to aircraft instrumentation, equipment and special mission needs.